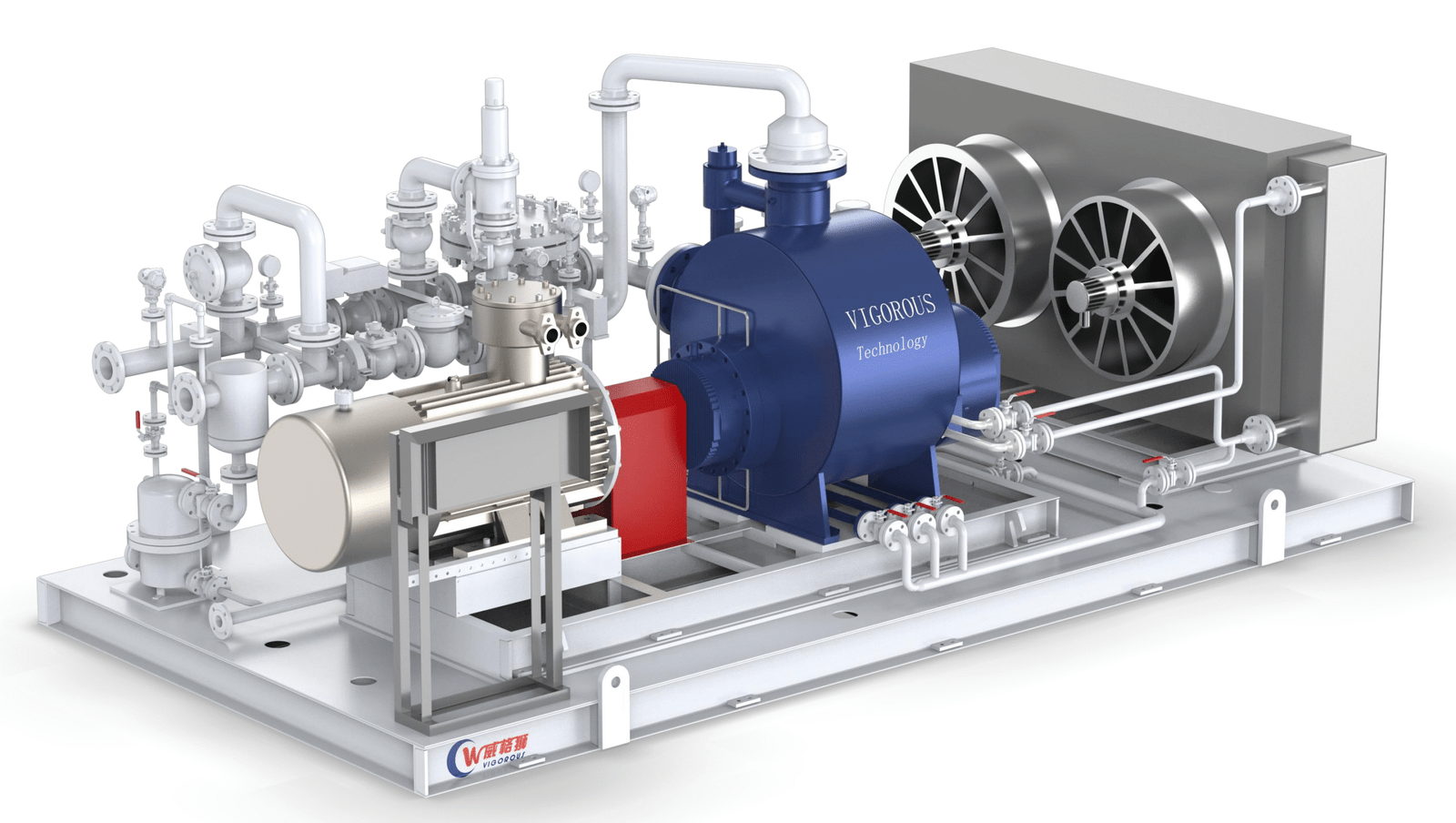

Main pump model: HWMPS450

It supports long-term transmission of mixtures with any full-liquid or full-gas ratio.

It supports long-term transmission of mixtures with any full-liquid or full-gas ratio.

Functional Features

- Higher gas compression capacity and outlet pressure balance control

- Long-term slug flow handling capability

- Relatively low equipment investment cost

Application Scenarios

Ideal for exploitation of water-flooded wells and coalbed methane wells.

Market Scale & Prospect

Major domestic oil and gas fields have significant demand for this equipment.

Changqing Oil and Gas Field alone has nearly 5,000 water-flooded wells, and Southwest Oil and Gas Field also needs large quantities.

The market prospect is promising, with an estimated scale of hundreds of billions of yuan.

Changqing Oil and Gas Field alone has nearly 5,000 water-flooded wells, and Southwest Oil and Gas Field also needs large quantities.

The market prospect is promising, with an estimated scale of hundreds of billions of yuan.

System Features

It combines the functions of a centrifugal pump and a compressor, with strong gas handling and compression capabilities.

The transmission medium can be 100% gas or 100% liquid.

For high-gas-content working conditions, the system has an external automatic liquid-replenishing cooling circuit.

This circuit connects to the pump chamber and uses an air-cooled heat exchanger to quickly lower the temperature of circulating liquid.

This ensures the system always operates within a safe range.

Using this system, oil, gas, water and small amounts of solids are centrally pressurized.

They are then transported to central processing facilities via a single pipeline, greatly reducing exploitation difficulty and equipment costs for water-flooded and coalbed methane wells.

The transmission medium can be 100% gas or 100% liquid.

For high-gas-content working conditions, the system has an external automatic liquid-replenishing cooling circuit.

This circuit connects to the pump chamber and uses an air-cooled heat exchanger to quickly lower the temperature of circulating liquid.

This ensures the system always operates within a safe range.

Using this system, oil, gas, water and small amounts of solids are centrally pressurized.

They are then transported to central processing facilities via a single pipeline, greatly reducing exploitation difficulty and equipment costs for water-flooded and coalbed methane wells.

Overcoming Slug Flow: A Global Challenge Solved

Based on working conditions and on-site requirements, an optional cooling system can be equipped.

This system includes a heat exchanger or cooling tank (for extremely high-gas-content scenarios).

It guarantees continuous system operation no matter what type of slug flow is encountered.

This system includes a heat exchanger or cooling tank (for extremely high-gas-content scenarios).

It guarantees continuous system operation no matter what type of slug flow is encountered.

评价

目前还没有评价